CUSTOM 1 PIECE FORGED WHITE TESLA WHEELS: RV-MS808

Free Shipping

Material

Custom-Made-Per Order

Please contact us to determine the custom details before placing your order, each of our products are produced according to the order requirements

- Available in 15"-26"

- Custom size, PCD, and centre bore

- Custom finishes are available

- 100% truly custom forged wheels | 10,000/12,000-ton forging line

Each set of wheels are individually designed and machined for any vehicle and any application

- Machined from aerospace-grade forged 6061-T6 aluminum alloy

- Max concavity designed for each vehicle's brake clearances

- OEM TPMS and lug compatible

- FEA tested to DOT safety standards

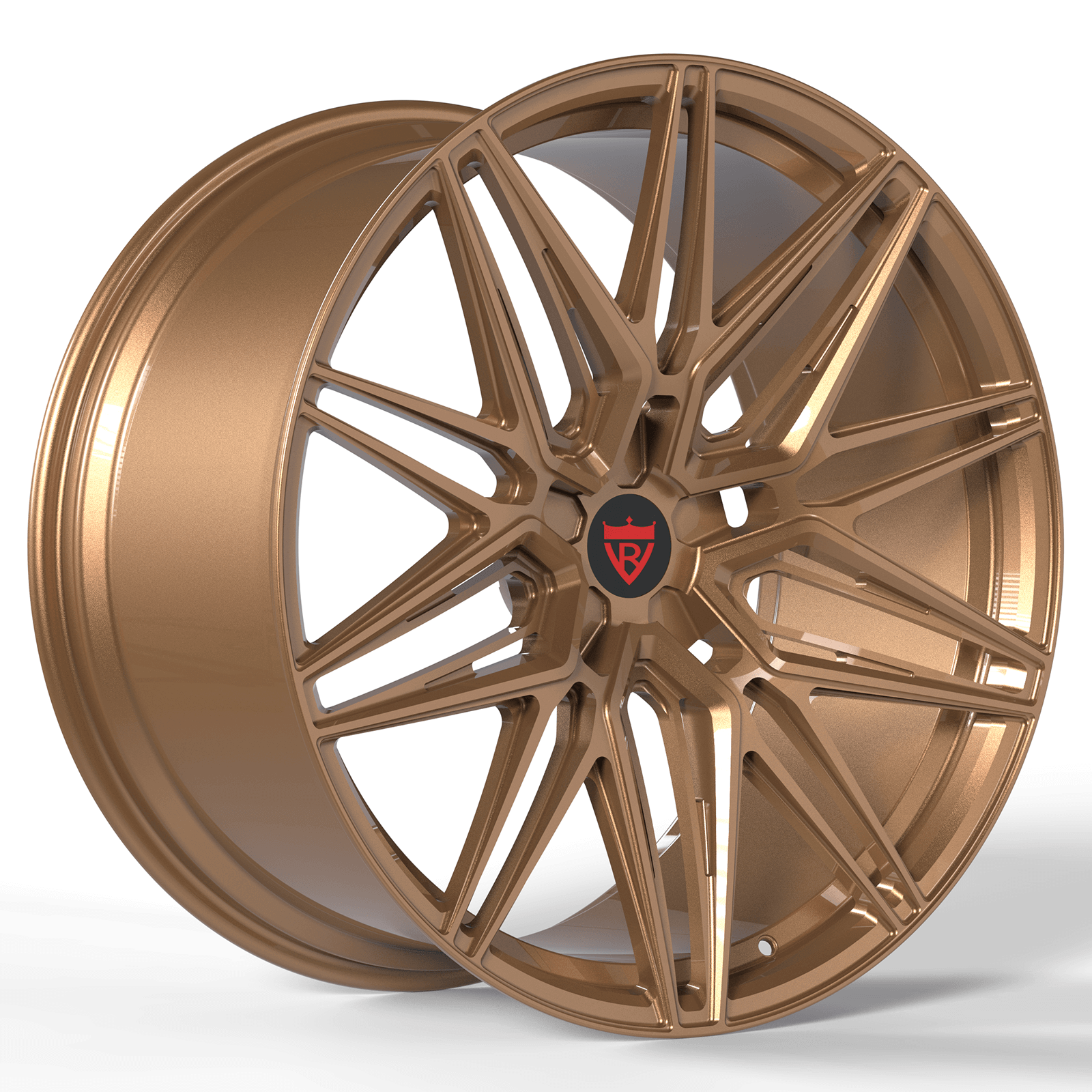

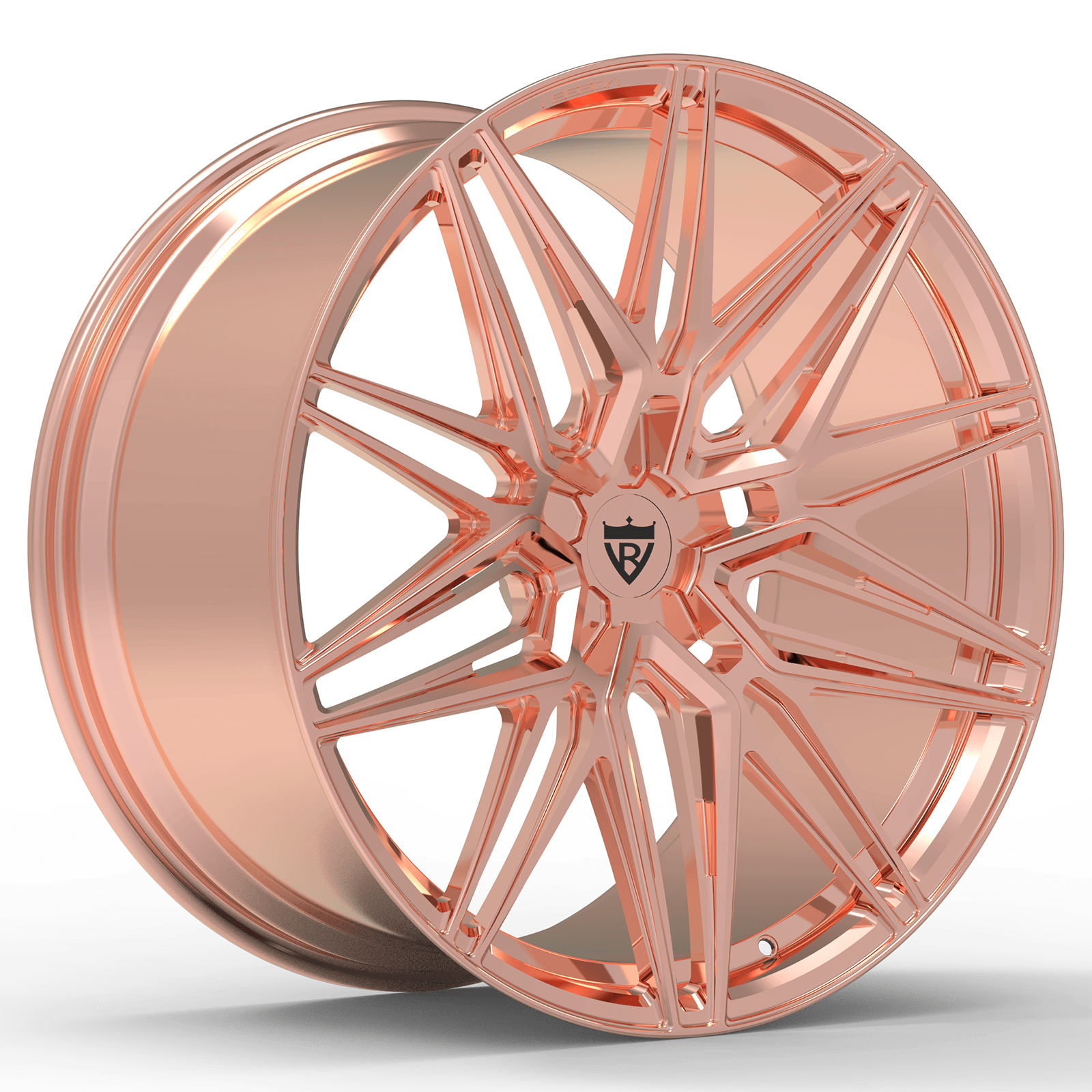

CONCAVE SPORTS STYLE

RV-MS808 Forged Series for Tesla five-lug applications are one-piece forged aluminum wheels designed and produced for performance-minded Tesla owners with a concave design, rim edge is flush with the fender for a fuller, sportier look.

AGGRESSIVE DESIGN

Forged Monoblock RV-MS808 Series, with aggressive design and split-spoke. The concave profile that provides a bold look for Tesla, RV-MS808 is available in 20x9.5 size and 2 custom finishes.

✔Finest Aerospace-grade 6061-T6 aluminum alloy

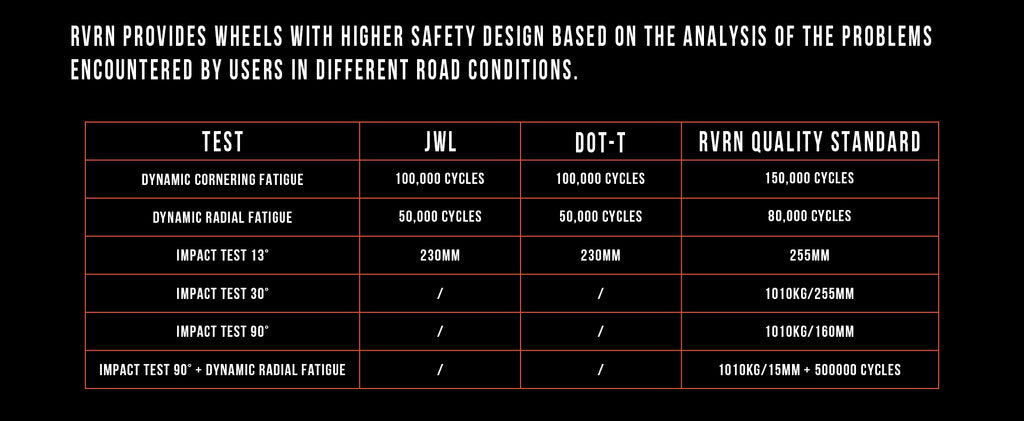

✔TUV,DOT,JWL Verified

✔10,000/12,000-ton forging line

✔ Powder-Coated Finish

✔Custom Per Order for Any Vehicle and Any Application

Our forged blanks are crafted from aerospace-grade 6061 magnesium aluminum alloy, on the same production lines of heavy machinery, high-speed rail and aircraft wheels, ensuring top-tier quality and performance. We take pride in using only brand-new raw materials, completely avoiding any recycled materials in our production process. At present, only a select few companies worldwide possess the expertise and capabilities necessary to handle these advanced production lines, and we are honored to be among them. With state-of-the-art forging facilities and an unwavering commitment to excellence, we guarantee unmatched quality in every forged wheel we produce.

Furthermore, our forged wheels are crafted alongside those produced for TOP brands on the same production lines. This shared production environment underscores the exceptional craftsmanship and uncompromising standards that define our products. Rest assured, when you choose our forged wheels, you're choosing unparalleled quality and reliability.

Forged 2-Piece Series: 4 weeks

Forged 3-Piece Series: 5 weeks

*Note: Chrome finish requires extra 7 days

Two-tone color required extra 5 days

Brushed/Polished finish requires extra 5 days

We understand you may have a lot concern about the fitment when it comes to purchasing a set of custom, made per order, forged wheels. While RVRN lists the key parameters for wheels and let you understand how EASY and QUICK to customize your own wheels.

All you need to do is tell us the WHEEL SIZE you need, RVRN engineer will take care of the rest by checking your vehicle official website and RVRN database.

- Available in 15"-26"

- Custom size, PCD, and centre bore

- Custom finishes are available

- 100% truly custom forged wheels | 10,000/12,000-ton forging line

Each set of wheels are individually designed and machined for any vehicle and any application

- Machined from aerospace-grade forged 6061-T6 aluminum alloy

- Max concavity designed for each vehicle's brake clearances

- OEM TPMS and lug compatible

- FEA tested to DOT safety standards

CONCAVE SPORTS STYLE

RV-MS808 Forged Series for Tesla five-lug applications are one-piece forged aluminum wheels designed and produced for performance-minded Tesla owners with a concave design, rim edge is flush with the fender for a fuller, sportier look.

AGGRESSIVE DESIGN

Forged Monoblock RV-MS808 Series, with aggressive design and split-spoke. The concave profile that provides a bold look for Tesla, RV-MS808 is available in 20x9.5 size and 2 custom finishes.

✔Finest Aerospace-grade 6061-T6 aluminum alloy

✔TUV,DOT,JWL Verified

✔10,000/12,000-ton forging line

✔ Powder-Coated Finish

✔Custom Per Order for Any Vehicle and Any Application

Our forged blanks are crafted from aerospace-grade 6061 magnesium aluminum alloy, on the same production lines of heavy machinery, high-speed rail and aircraft wheels, ensuring top-tier quality and performance. We take pride in using only brand-new raw materials, completely avoiding any recycled materials in our production process. At present, only a select few companies worldwide possess the expertise and capabilities necessary to handle these advanced production lines, and we are honored to be among them. With state-of-the-art forging facilities and an unwavering commitment to excellence, we guarantee unmatched quality in every forged wheel we produce.

Furthermore, our forged wheels are crafted alongside those produced for TOP brands on the same production lines. This shared production environment underscores the exceptional craftsmanship and uncompromising standards that define our products. Rest assured, when you choose our forged wheels, you're choosing unparalleled quality and reliability.

Forged 2-Piece Series: 4 weeks

Forged 3-Piece Series: 5 weeks

*Note: Chrome finish requires extra 7 days

Two-tone color required extra 5 days

Brushed/Polished finish requires extra 5 days

RVRN

CUSTOM PER ORDER

Monoblock Fully Forged Performance Wheel Series

RVRN

RVRN

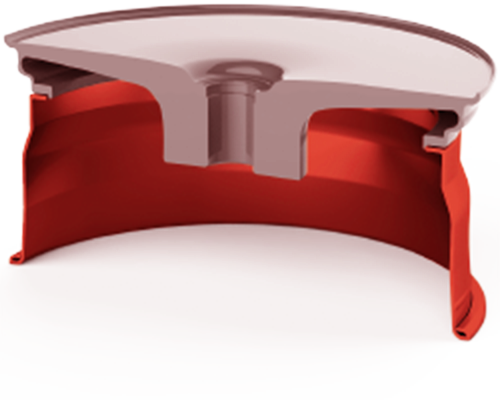

The forged process

DESIGN PROCESS

15 senior engineers with more than 10 years experience. Trying to explain and develop a visual idea about the custom forged wheels in your head can feel like translating into a language you don’t speak - frustrating and ultimately inaccurate. Using parametric CAD software, our designers render 3D models of your concept to aid the visualization process, and tweak it based on your feedback until it looks exactly how you imagined it.

ENGINEERING

The models aren’t just for looks. We use them to implement weight reduction and performance strategies, assessing and modifying features against design intent. We run them through rigorous computer simulations in order to stress-test your design, pinpoint potential stress-points, predict it’s performance and ensure it is in compliance with all safety standards. The end result is a totally optimized wheel.

MANUFACTURING

Your custom wheels are created to spec using high-precision CNC Machining that surpasses the accuracy, capacity and reliability of human hands. We use forged 6061-T6 aerospace-grade aluminum alloy - aluminum favoured for it’s strength-to-weight ratio, alloyed with magnesium and silicon and other metals for increased stress, corrosion and crack resistance and better formability. Hand finished to your specifications to create your customized wheels.