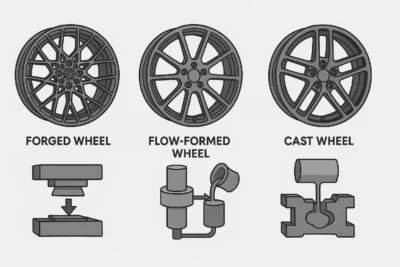

How forging pressure affects wheel strength, fatigue life, and precision — especially for large-diameter and performance builds

When customers search for forged wheels, most comparisons focus on design, finish, or concavity. However, one of the most critical factors behind wheel strength and long-term reliability is often overlooked:

forging press tonnage.

In forged wheel manufacturing, pressure does not simply shape aluminum into a wheel blank. At sufficient tonnage, forging pressure fundamentally changes the internal structure of the material, directly impacting strength, fatigue resistance, and dimensional accuracy. This is why forging press capacity plays a decisive role in high-performance and large-diameter forged wheels.

Why Forging Pressure Dictates Wheel Strength

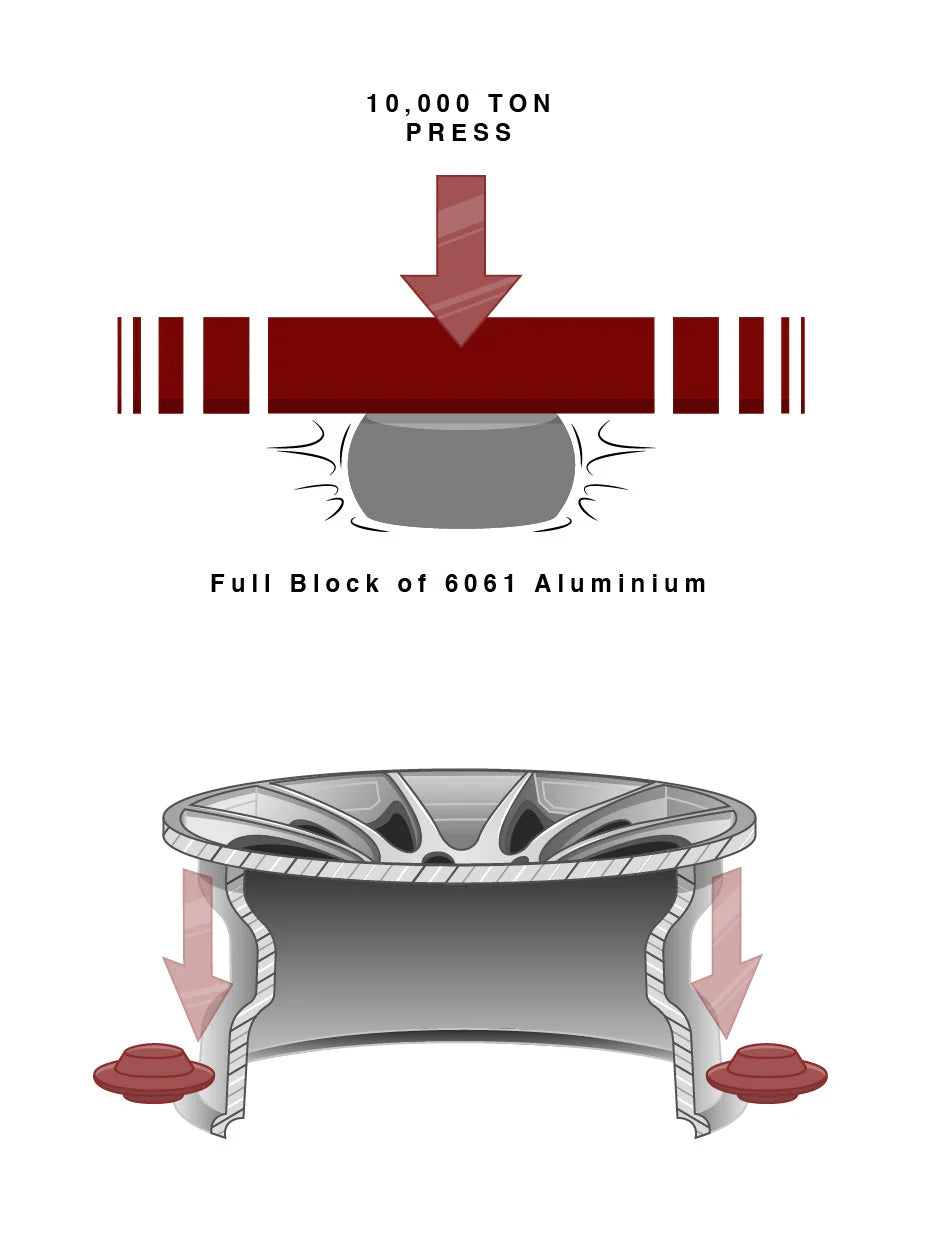

Forging is a controlled deformation process. When aluminum is compressed under extreme pressure, its internal grain structure is forced to flow in the direction of stress rather than remaining randomly oriented.

Higher forging pressure results in:

-

Refined grain flow that follows load paths

-

Increased material density with fewer internal voids

-

Improved fatigue resistance under repeated stress

These factors are essential for wheels designed for high-horsepower vehicles, heavy platforms, and real-world road conditions where impact and cyclic loading are unavoidable.

How Forging Pressure Changes Wheel Performance

Higher Material Density

Greater forging tonnage compresses aluminum more thoroughly, minimizing internal inconsistencies and porosity. This produces a denser structure capable of withstanding higher impact loads and extreme driving conditions.

For large-diameter forged wheels, higher density is critical to maintaining structural integrity without excessive weight.

Improved Fatigue Resistance

Fatigue failure is one of the most common long-term issues in wheels, particularly on performance vehicles. Each acceleration, braking event, and road impact introduces stress cycles that accumulate over time.

High-tonnage forging refines grain structure to resist crack initiation and propagation, significantly extending the wheel’s service life compared to lower-pressure processes.

Greater Dimensional Precision

Higher forging pressure allows aluminum to fully fill complex molds, enabling:

-

Deeper concave profiles

-

Thinner yet stronger spoke designs

-

Tighter tolerances across the barrel and face

This level of precision becomes especially important in large-diameter forged wheels (21–23 inches), where structural margins are naturally reduced by scale.

Enhanced Surface Integrity

Because higher-pressure forging produces a more uniform and compact structure, it also improves post-machining surface quality. Benefits include:

-

Better coating and finish adhesion

-

Reduced risk of micro-imperfections

-

More consistent results across polished, brushed, and chrome finishes

This directly impacts long-term finish durability, not just initial appearance.

6,000-Ton vs 8,000-Ton vs 10,000-Ton Forging Presses

Not all forged wheels are produced under the same forging pressure. Across the industry, forging press capacities typically range from 6,000 to 10,000 tons.

| Forging Press | Typical Application | Structural Margin | Design Freedom |

|---|---|---|---|

| 6,000-ton | Standard street forged wheels | Adequate | Limited |

| 8,000-ton | Performance aftermarket wheels | Improved | Moderate |

| 10,000-ton | Large, aggressive forged wheels | Maximum | High |

Lower-tonnage presses are sufficient for many standard applications. However, as wheel diameters increase and designs become more aggressive, higher forging pressure provides a critical structural advantage

Why RVRN Invests in 10,000-Ton Forged Wheel Technology

RVRN positions itself in the upper technical tier of the forged wheel industry. Rather than optimizing solely for styling or production efficiency, RVRN prioritizes structural margin and long-term reliability.

All flagship molds and premium wheel series are formed using 10,000-ton forging presses, enabling:

-

Greater strength in large-diameter and deep-concave designs

-

Consistent quality across complex geometries

-

Improved fatigue performance for high-power and performance-focused builds

This investment reflects a long-term engineering philosophy: technology, not aesthetics alone, builds trust.

What This Means for Customers and Partners

For Customers

-

Increased confidence in large and aggressive wheel designs

-

Stronger wheels with improved fatigue life

-

Long-term durability under real driving conditions

For Dealers and Partners

-

Lower claim and warranty rates

-

Higher customer satisfaction

-

Clear technical differentiation in the premium forged market

By focusing on forging pressure and material science, RVRN delivers products engineered beyond visual appeal.

Forged Wheel Press Tonnage: Frequently Asked Questions

Is a higher ton forging press always better for wheels?

Higher forging tonnage improves material compression and grain refinement. While standard vehicles may not always require it, higher pressure provides essential structural margin for large-diameter or performance-oriented wheels.

Do 10,000-ton forged wheels make a difference in daily driving?

For typical driving, the difference may not be immediately noticeable. However, under high loads, poor road conditions, or repeated stress cycles, higher forging pressure offers greater long-term reliability.

Are all forged wheels produced with the same forging pressure?

No. Forging press tonnage varies by manufacturer and application, typically ranging from 6,000 to 10,000 tons depending on equipment and design goals.

Engineering Before Aesthetics

In the forged wheel industry, forging pressure is not a marketing claim — it is an engineering variable that directly affects performance and durability.

By investing in 10,000-ton forging technology, RVRN ensures that its wheels are built not only to look aggressive, but to perform reliably under demanding real-world conditions.